The synthesis of polymer particles of different sizes includes both chemical and physical production methods.

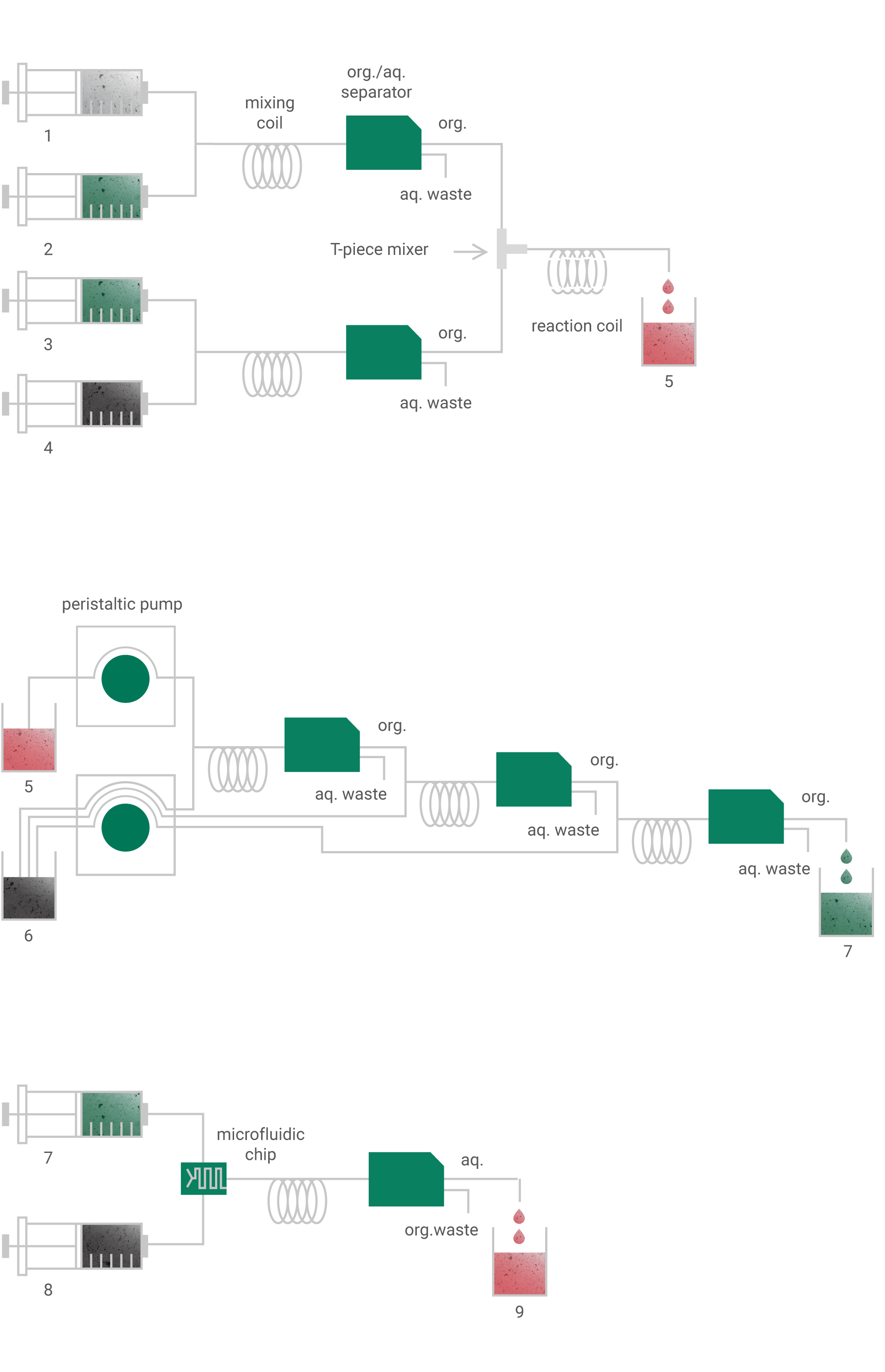

Chemical methods of synthesis in controlled streams of solvents allow to obtain multilayered API particles and biopolymers that facilitate prolonged release and maintenance of plateau concentration of the therapeutic agent in plasma. Flow systems with single or multiphase fluid flow levels provide non-trivial and unique technological solutions that are created to suite individual formulations. Manipulation of liquid solubility and flow rates allows to clearly define the morphological properties of particles and their size in accordance with the technical task. Physico-chemical methods for obtaining polymer particles are generally based on multiphase solvent systems with subsequent parameterization of emulsion dispersion.

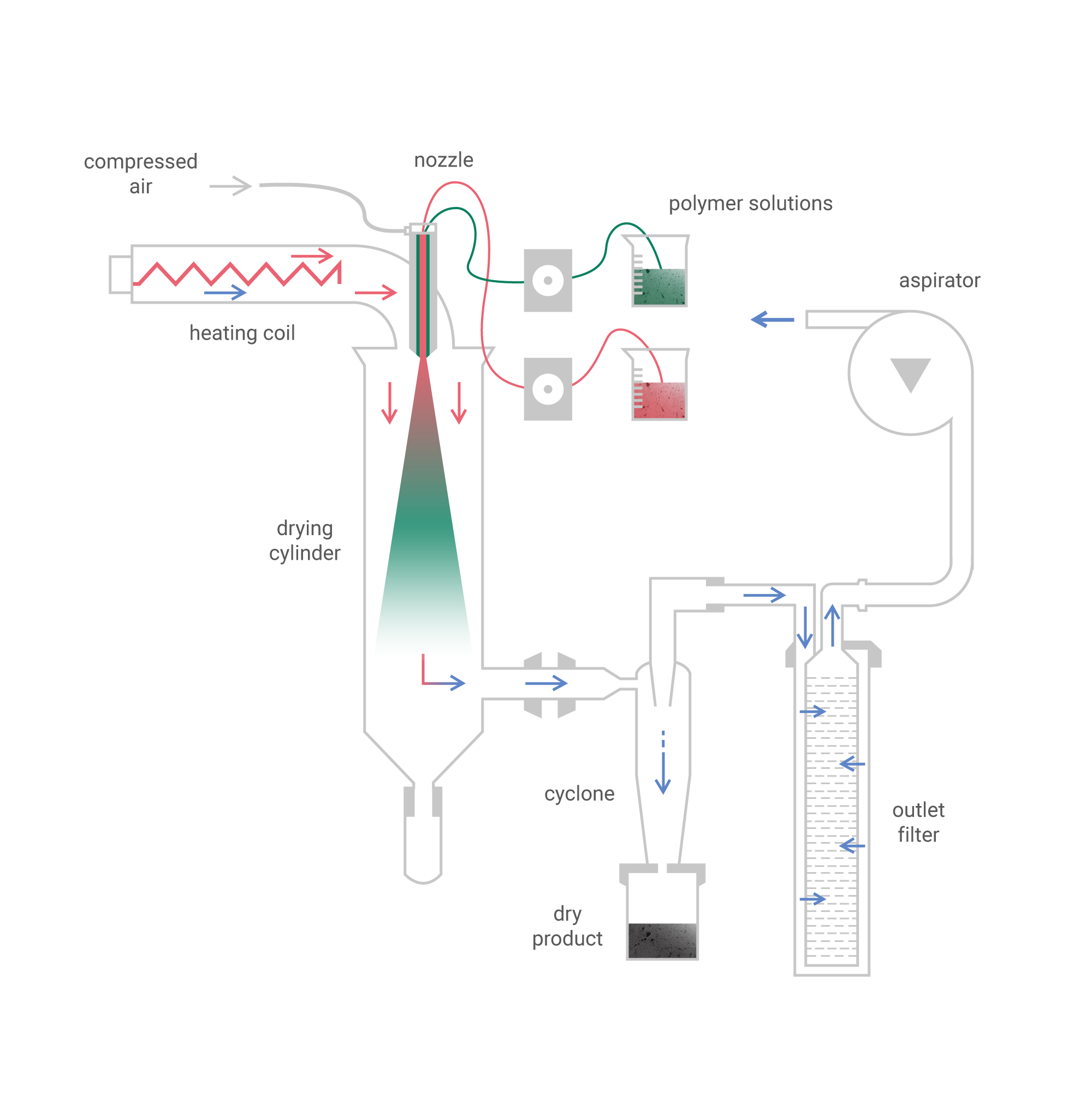

Physical methods of processing macromolecular compounds mainly apply multi-nozzle spray dehumidifiers in the flow of inert gas with subsequent fractional sieving on screening plants. Particles undergo stages of dialysis purification or ultrafiltration followed by lyophilization to ensure sterility of the obtained products.

Standard methods of organic synthesis have been used to attach specific ligand compounds to the surface of polymer particles, and advanced reaction mechanisms have been developed applying microwave heating and photorereaction with ultraviolet radiation to reduce the amount of toxic non-recyclable chemical waste.